Condensed Aerosol Fire suppression systems

|

|

|

|

The Forest Products Industry is important to the worlds economy. Forest Fires are a world wide problem costing millions of dollars a year.. One source of these fires is the equipment used to harvest trees deep in the forests. These locations are normally miles away from organized fire brigades. A broken hydraulic or fuel line can lead to major damage or loss of expensive equipment or worse start a ravaging forest fire. Portable extinguishers are provided but often prove to be too little too late. PyroGen has a better idea.

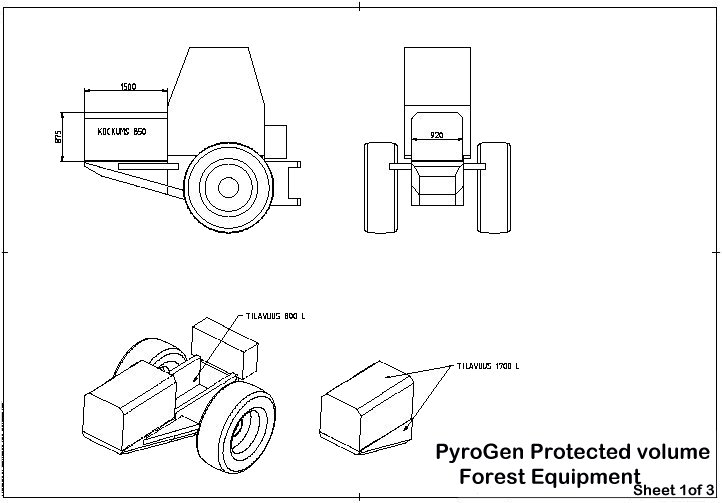

PyroGen UK Ltd has designed a pre engineered system to eliminate this threat. Protecting expensive equipment miles from the fire brigade is important. Protecting the world forests from fire is a bigger responsibility, PyroGen provides fire protection better than HALON and with out the environmental impacts of CFC's or HFC's. With no Global Warming Potential (GWP) or Ozone Depletion Potential (ODP), PyroGen fills this global requirements today and for the future as well. Below is a test protocol designed to test Pyrogen's effectiveness in real world fire scenarios.

PyroGen provides protection for Skidders, Booms, Drags, Wenches and cable gear. Debarkers and Chippers, Boom loaders. Tractors, Trucks, Crawlers, Dozers, Yarders, Fellers, Bunchers and even Portable Saw Mills. All forest industry machinery regardless of manufacture can have modern effective fire protection, we even have an extinguisher for your chain saw.

DIRECTIONS OF FULL SCALE FIRE

TEST

FOR FOREST AND OTHER MACHINES

0. General

This is a draft document but it

shall

be applied for the tests.

1. Technical requirements

The full scale test shall be carried

out on a test machine. The machine shall be provided with a Turbo and

an

Engine. The engine must be able to run. The engine space must be

complete with covers and the minimum volume shall be 2 m3. The engine

must

be provided with a manual engine stop. The test will be carried out in

any weather circumstances.

2. Materials and liquids being used as Fuels

2.1 Sawdust / slivers

6.2 kg sawdust / slivers with absorption of equal amount of liquid including 50 % diesel oil, 25 % hydraulic oil and 25 % waste oil. The mixture shall be prepared 24 hours before the tests start.

2.2 Waste cotton

Three (3) m twisted waste cotton with absorption of ignition liquid. The absorption time shall be five minutes.

2.3 Liquid 1

Three (3) litters liquid

including

of 60 % diesel oil, 20 % hydraulic oil and 20 % grill ignition liquid,

pressurized to 1.4 MPa

2.4 Liquid 2

Two (2) litters hydraulic oil pressurized to 1.4 MPa

3. Preparing of the test

machine

Preparing of the test machine is

done

by a person who is a member of the SBF:s committee or by an appointed

person.

The Engine space and space below the driver cabin, if existing, is

prepared

with mixture 2.1. After that liquid 1 is sprayed on the engine and to

the

space under the cabin. Waste cotton is laid in the engine space and to

the space under the cabin.

4. The

test procedure

The engine is started and it runs

30 minutes in idle. In seven minutes run speed is controlled to 1700 -

1800 RPM. If there is not a turbo, a mock is installed and fastened to

the engine cover in the exhaust side. The machine is ignited using

waste

cotton laying on the both sides of the engine. The burning time is 45 s

and after that the liquid 2 is sprayed on the both sides and on the

turbo.

When the total burning time 90

seconds

has been reached, the engine is stopped and the extinguishing system

released.