FAA orders airlines to install new fuel tank inerting

system to reduce chance of explosion

A cost-benefit analysis still must be done and airlines need time to

plan for the change, so the requirement is not expected to take effect

for at least two years. Once the rule is issued, the

fuel-tank inerting program will be phased in over seven years. During

that time existing planes will have to be retrofitted with the device

and new planes will have them as standard equipment.

15 February 2005

Flammability Reduction Means

(Fuel Tank Inerting) - FAA SPECIAL

CONDITIONS No. 25-285-SC

Read

more

Special Conditions: Boeing Model 747-100/200B/200F/200C/SR/SP/100B/300/ 100B SUD/400/400D/400F

Airplanes; Flammability Reduction Means (Fuel Tank Inerting); Final Special Conditions; Rule

Propulsion and Mechanical Systems Branch, FAA, ANM-112.

StillBrooks Labs secures

new testing facility. This 31,500SqFt is the new home for the

Materials Lab and new larger fire HOT room. Located near UL in

Chicago the planning and construction schedule are under way.

A International marine organization (IMO/Cir1007) 500M3

.total flooding test chamber is still planed for the close end of this

building, along with 100M3, 50M3 25M3, 10m3 5m3

and small scale devices. This will allow for full scale agent

development testing and third party approvals all in one location . We

will relocate all of our current test fixtures to this location and

combine the data acquisition system, digital video monitors all into a

central control room for ease of operation. Sitting on 3.5 acre

with a chain link fence and barbed wire the facility is secure and will

allow for improved security clearance on our military programs.

An additional 17,000 SqFt office complex is located on an additional 4

acres adjacent to the fire lab.

The

The

Cargo Bay is next..

SBL and FirePASS developed

the first "Gate to Gate" fire Suppression system for commercial

airliners

StillBrooks Laboratories and Fire Pass have

prefecting a

novel method of protecting airliner cargo compartments and dry

bays. Low

Pressure water mist is proving to be an answer to Halon

Replacement in commercial aircraft cargo compartments. When combined

with Hypoxic air the patented lcombination is far

surpassing any halon alternative material tested to date. In

the links below the temperature and test data as shown. Minimum

Performance Standard for Aircraft Cargo Compartment Halon

Replacement

Fire Suppression Systems final rule was issued this summer.

Federal Aviation Regulations (FARs) and Joint Airworthiness

Requirements (JARs) require fire suppression systems for some

classifications of cargo compartments. In the past, the aircraft

industry selected Halon 1301 total flood fire suppression systems as

the most effective means for complying with the regulations. Because of

the ban on production of Halon 1301 (effective January 1994, as

mandated by the Montreal Protocol), new fire suppression systems will

need to be certified when Halon 1301 is no longer available. The tests

described in this standard are one part of the total Federal Aviation

Administration (FAA) and the Joint Aviation Authority (JAA)

certification process for cargo compartment fire suppression systems.

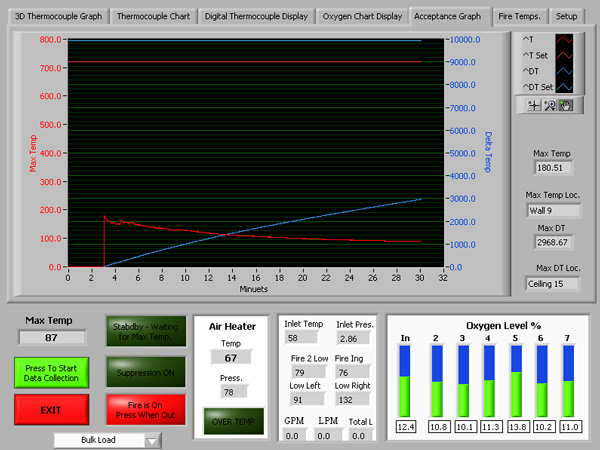

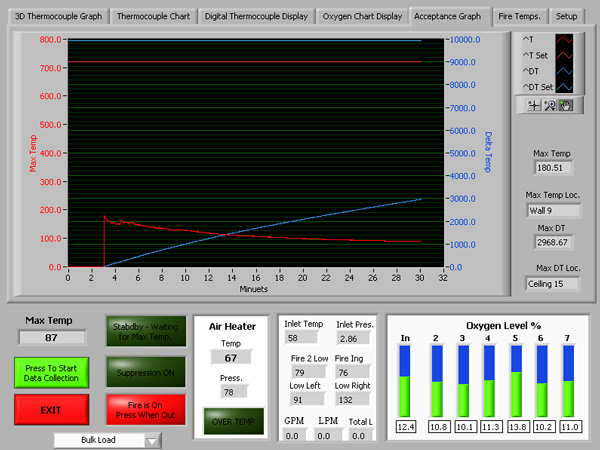

In the Minimum Performance Standard data screen below

the red line

(maximum device temperature) and the blue line

(accumulated maximum temperature over time), can not cross the Halon

1301 level

of safety (upper flat matching color lines). If the data does not

exceed the level of safety demonstrated with HALON the alternative

agent passes. The test MPS was developed in conjunction

with the International Aircraft Fire Protection Systems Working Group

(IAFPSWG), over the last five years. In the below chart the systems

passed the FAA requirements. To date every test has been better

than HALON 1301. Temperature column shows values 1" below the ceiling

and along the side walls of the device. Oxygen column shows O2

concentrations at 5 locations inside the device, and the input.

The Mister pressure on the below test was at 2.86 psi ( yes two and

three

quarter pounds). The Low Pressure Dual Fluid misting nozzle was

developed by NAVAIR in the mid 90's. It has been used on several

full scale aircraft and flight test. One big advantage if the nozzle is

it will not clog, and it performs well from 2 through 100 psi.

Mixing the water and Hypoxic conditioning air and variable pressures

and

still obtaining the same size water droplet. Water enhance were

also successfully tested. It is felt that they will help prevent flame

spread and help wet the area as the O2 levels are reduced. The

mister is

capable of dispensing the water horizontally up to 7 meters at one bar

pressure. The best part is everything is already on the aircraft,

air-conditioning, water, Interting system membranes, Its too

easy.

Check back for more details and test data.

Screen grabs from the

DAQ system at the end of each test on these links

- HOME

- US EPA, SNAP, ISO, ICAO,

FAA US DOT,

NFPA, SAE, FM, NIST, ATA, UL, SSL, AS/NZS, ODP , GWP , Pyrogen ,

PYROGEN

, Airline Cargo conversions , Class A fire , Class B fire , Class C

fire

, EMAA, Encapsulated Micron Aerosol Agent, FAR 25. Aircraft Cargo

Fires,

Telecommunications fires , Transportation fires , Petrol chemical fires

, Fire detection, Automobile Fire , Truck fires , Train fires ,

Building

fires , Structural fires , petroleum fires , engine fires , marine

fires

, cargo fires , wood fires , Halon flooding , UL 1058, aircraft fire

protection

, aircraft crash , airline cargo fire , airline fire protection , FAA

Technical

center , Oil rig fires , gas rig fires , vehicle fires , electrical

fire

suppression , computer room fires , ship fires , machinery fires ,

merchant

vessel fires , train fires , generator fires , battery fires , Wheel

fires

, brake fires , tire fires , car fires , home fires , Loss productivity

, boeing fire test , 737 fire test , NRL , Naval Research

Laboratory

, Naval air systems command , NASC , NAVAIR , AS/NZS 4487:1997 ,

Joint strike fighter , JSF, HARC , NTSB , Transport canada , NIST , FAA

Technical Center , Thermal Acoustic Insulation Blankets , IMO ,

International

Maritime commission , USCG , United states coast guard , MCA , Pyrogen

Ltd. Pyrogen Corp. Sdn. Bhd. , IAFC , IFPA ,