The

below test was run for 90 minutes (1.5 Hours) with a constant

12.90~13.10 amps fed to

the NiCrome wire. This amount of damage is considered to be

negligible. The internal temperatures were around 350 deg F from T+3 to

T+20. Then the internal temperature dropped to around 200 F and

stabilized (believed to be heat from the hot wire). At T+45 the inlet

O2 was raised 1% at T+65, it was raised another 1%, at T+85 another 1%

and the test terminated at T+90 Click on the photos of a larger

photo. ( yes it's the same box as test one, Just new paper inside)

The

below test was run for 90 minutes (1.5 Hours) with a constant

12.90~13.10 amps fed to

the NiCrome wire. This amount of damage is considered to be

negligible. The internal temperatures were around 350 deg F from T+3 to

T+20. Then the internal temperature dropped to around 200 F and

stabilized (believed to be heat from the hot wire). At T+45 the inlet

O2 was raised 1% at T+65, it was raised another 1%, at T+85 another 1%

and the test terminated at T+90 Click on the photos of a larger

photo. ( yes it's the same box as test one, Just new paper inside) |

This

is the second of the series and the last prior to the briefing to be

given to the International Aircraft Systems Fire Protection Working

Group, in Atlantic city NJ on Nov. 6, 2003. A copy of the presentation

will be made available at a link below, after the meeting. |

||

|

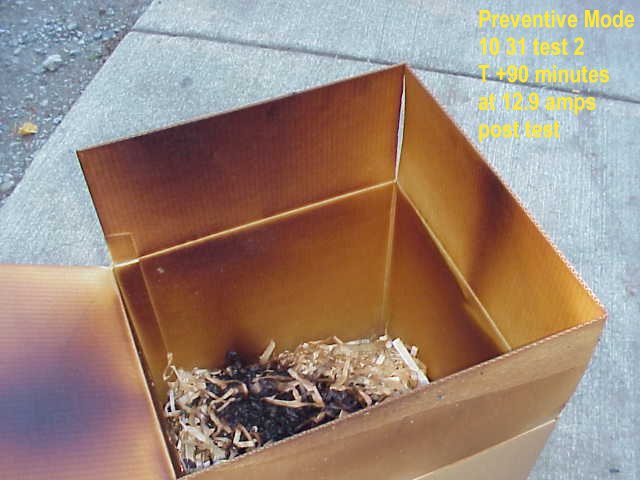

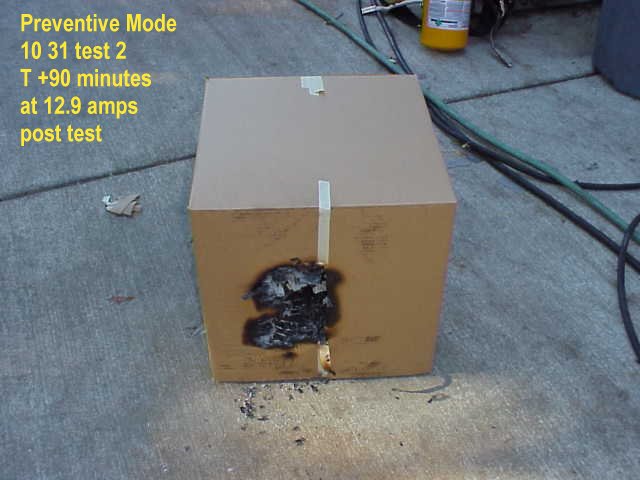

As

in the last test hypoxic air was applied, after

the atmosphere was reduced to 14.5% oxygen, the

115Vac was applied to the system (T+0) , This photo is T+90

minutes after application of the power to the NiCrome wire. In

this view the box appears normal. (this is also the same box used in the previous test) |

||

|

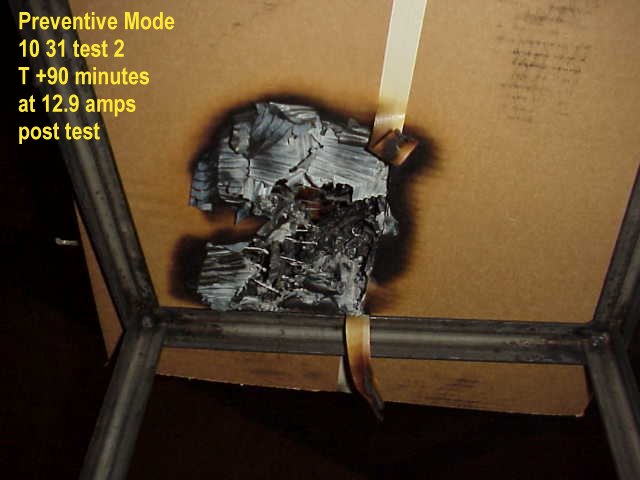

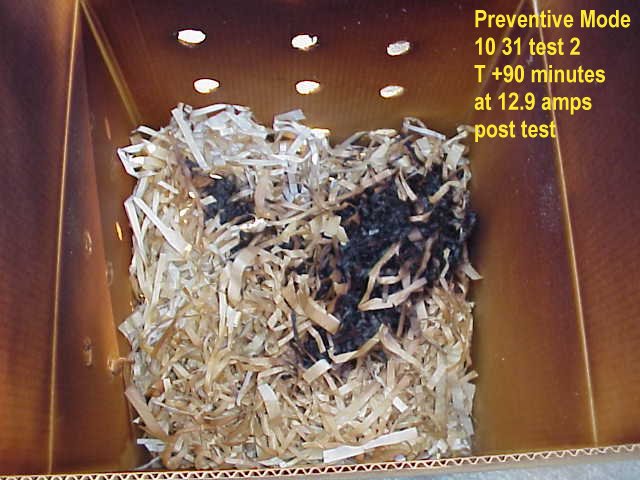

After

the box internal temperatures stabilized and no apparent flames the O2

was increased every 20 minutes

until a change in the temperature was observed. At 15.2% a

increase in temp was observed. Sparks and ash was observed starting at

the T+43 minutes falling from the box. This hole was found on post test

inspection. |

||

|

As you can see

here the

igniter wire fell to the bottom and burned a hole in the bottom of the

cardboard with no visible flames over a 90 minute test. |

||

|

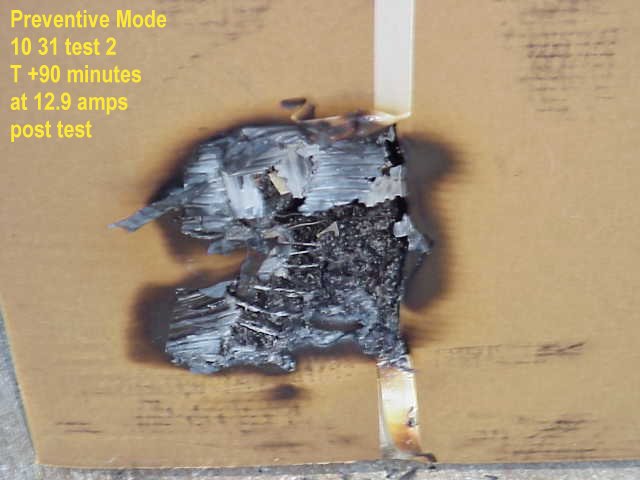

In this photo

the damage to

the contents of the box is quite evident. Discoloration and scorching

is apparent. Total loss of weight of the

box was around that 90 grams (1 gram per minute) |

||

|

Once

again the Hypoxic air prevents the growth of the fire. Damage it

limited to the paper being exposed to the radiant heat from the NiCrome

wire. The internal temperatures exceeded 350 F producing large quantities of smoke, but no flame. |

||

|

T+90

damage is limited to 90 grams of weight loss and a hole burned through

the bottom of the box. The holes appears to be caused by the wire

dropping to the bottom of the ignition box. The wire was touching

the inner liner after the test. |

||

| Low Pressure Dual Fluid Water Mist (LPDF) and Hypoxic Air as a Viable HALON Alternative | PDF

copy available at this link |

||