FAA orders airlines to install new fuel tank inerting system to reduce chance of explosion

Hypoxic Air Suppression test

| IAI Faa Halon Replacement Agent MPS test Hypoxic air

Preventive test fires are located inside this device, Minimum Performance Standard for Aircraft Cargo Compartment Halon Replacement Fire Suppression Systems

|

|

||||

|

FAA

MPS Starter Box. This standard flame source produces a fire that will

raise the cargo compartment to above 500 Deg F in under 2

minutes. In this 180 minute test the

power to the NiCrome wire is applied at 14% Oxygen and held for three

hours. This is the longest test to date. A after the internal

temperature of the starter box stabilized at 122 deg F Deg the test is

basically

over. Like "watching paint dry" the box will stop smoking, the

atmosphere

is cleansed by the constant Hypoxic airflow and after 20 minutes it

just sits there.

|

||||

|

Cargo

Compartment simulator used for the test. The starter box is

placed in a stand in the center of the volume. The atmosphere is

conditioned with Hypoxic

air, then the power is applied. This is the first true "Gate to

Gate" suppression system developed for commercial airliners. |

||||

|

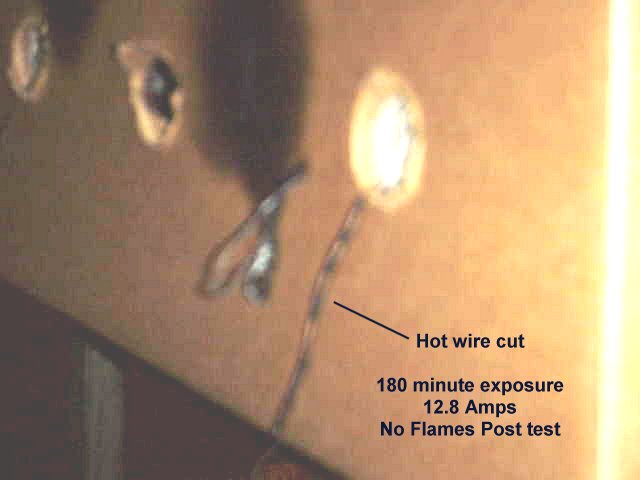

Post

test, showing three extra access holes placed in the opposite

side to add to the viewing angle from another camera view on the

inside. This modification proved to be little help, due to the smoke

desnity, and no flames to observe inside the box |

||||

|

Damage to the front side from the Hot Wire. What looks like the wire on the right is actually a slit burned in the exterior of the box by the hot wire. The two dark spots are caused by the hot wire migrating inside and the protruding coils burning through from the inside. | ||||

|

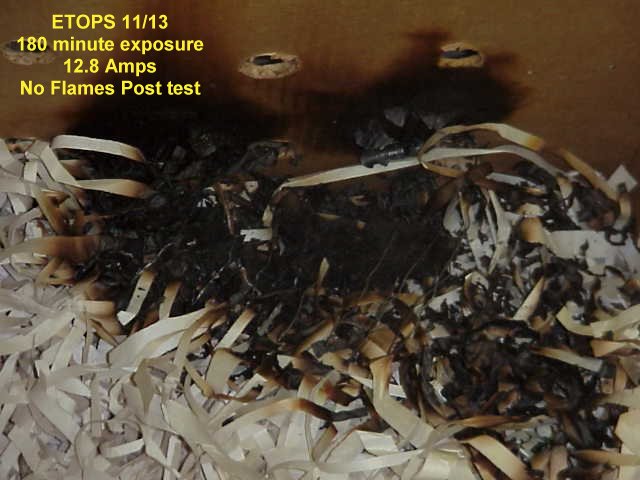

Note

no external damage Although this does show some heat discolor and smoke

stains there is some char, but not too bad for three hours of

exposure |

||||

|

Again

internal damage to the paper is limited to the radiant heat produced by

the hot wire. After the paper has "smoked out" to charcoal, the

temperature stabilized

at 122 Deg F at 13 minutes and remained there for the rest of the 180

minute test. |

||||

|

Internal

fuel load. Note the shredded paper in the box. The Hypoxic

air was able to suppress this before

it migrated into the deep

seated fuel pile. . |

||||

|

This

test series, considered to be one of the hardest to suppress is

typical of the efficiency of the Low Pressure Dual Fluid water mist and

Hypoxic

air. With no water to control heat, the flame

was suppressed only by the Hypoxic atmosphere eventually attaing

extinguishment levels.

Reduced flammability of

airliners is our goal, At II Fire lab we are getting there

|

||||

Home

US EPA, SNAP, ISO, ICAO, FAA US DOT, NFPA, SAE, FM, NIST, ATA, UL, SSL, AS/NZS, ODP , GWP , Pyrogen , PYROGEN , Airline Cargo conversions , Class A fire , Class B fire , Class C fire , EMAA, Encapsulated Micron Aerosol Agent, FAR 25. Aircraft Cargo Fires, Telecommunications fires , Transportation fires , Petrol chemical fires , Fire detection, Automobile Fire , Truck fires , Train fires , Building fires , Structural fires , petroleum fires , engine fires , marine fires , cargo fires , wood fires , Halon flooding , UL 1058, aircraft fire protection , aircraft crash , airline cargo fire , airline fire protection , FAA Technical center , Oil rig fires , gas rig fires , vehicle fires , electrical fire suppression , computer room fires , ship fires , machinery fires , merchant vessel fires , train fires , generator fires , battery fires , Wheel fires , brake fires , tire fires , car fires , home fires , Loss productivity , boeing fire test , 737 fire test , NRL , Naval Research Laboratory , Naval air systems command , NASC , NAVAIR , AS/NZS 4487:1997 , Joint strike fighter , JSF, HARC , NTSB , Transport canada , NIST , FAA Technical Center , Thermal Acoustic Insulation Blankets , IMO , International Maritime commission , USCG , United states coast guard , MCA , Pyrogen Ltd. Pyrogen Corp. Sdn. Bhd. , IAFC , IFPA ,