FAA orders airlines to install new fuel tank inerting system to reduce chance of explosion

A cost-benefit analysis still must be done and airlines need time to

plan for the change, so the requirement is not expected to take effect

for at least two years. Once the rule is issued, the so-called

fuel-tank inerting program will be phased in over seven years. During

that time existing planes will have to be retrofitted with the device

and new planes will have them as standard equipment. The

Cargo Pit is next !

This system is 90% of

what is required for the cargo system, WE are one valve away > >IAI fire lab test Preventive Mode in the suppression test method device

The below sequence of photos

demonstrates the effectiveness of the "FirePASS

Preventive" mode of Hypoxic Air and Low Pressure (LPDF) Water Mist

System. After several week of successfully passing the fire test

scenarios for halon replacement agents, the IAI fire lab started phase

two of the system test. Prevention of fire. We feel it is easier not to

have a fire, that to try to control one after it starts. In the below

sequence the standard deep seated class A fire starter box from the FAA

bulk load and containerized fire scenarios is put to the extreme test.

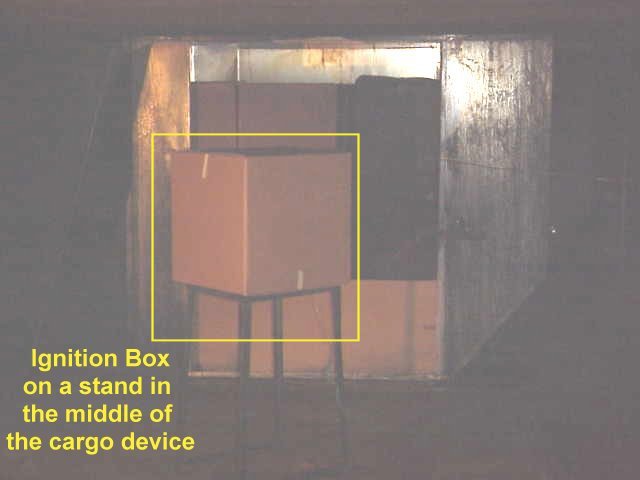

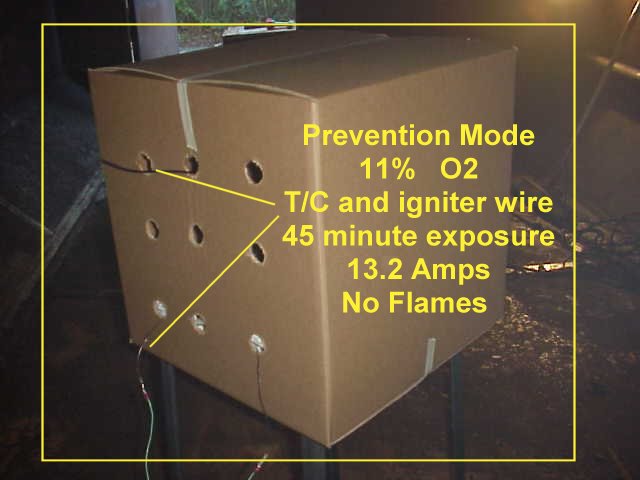

The Box is placed on a steel frame at the mid point of the 2000 CuFt cargo compartment test fixture. The air side of the misting system is activated driving the Oxygen content down to below the combustion level. When the O2 content reached 14.5% inside the compartment 115 Volts 60Hz at 13.2 amps is applied to a NiCrome wire wrapped around several paper towels. This ignition method is used in the FAA MPS test method and always produces a sustained fire in 60 seconds. The airflow rates are the same use in previous bulk load and containerized fires using LPDF water mist.

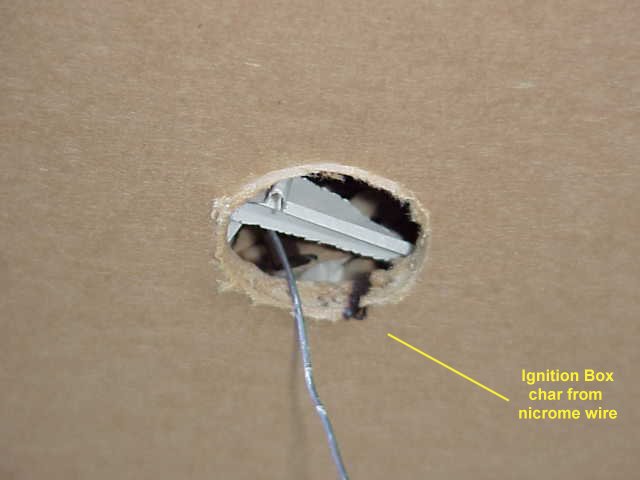

The below test was run for 45 minutes with a

constant 13.20 amps fed to

the NiCrome wire. This amount of damage is considered to be

negligible. Click on the photos of a larger photo

The below test was run for 45 minutes with a

constant 13.20 amps fed to

the NiCrome wire. This amount of damage is considered to be

negligible. Click on the photos of a larger photo

The Box is placed on a steel frame at the mid point of the 2000 CuFt cargo compartment test fixture. The air side of the misting system is activated driving the Oxygen content down to below the combustion level. When the O2 content reached 14.5% inside the compartment 115 Volts 60Hz at 13.2 amps is applied to a NiCrome wire wrapped around several paper towels. This ignition method is used in the FAA MPS test method and always produces a sustained fire in 60 seconds. The airflow rates are the same use in previous bulk load and containerized fires using LPDF water mist.

The below test was run for 45 minutes with a

constant 13.20 amps fed to

the NiCrome wire. This amount of damage is considered to be

negligible. Click on the photos of a larger photo

The below test was run for 45 minutes with a

constant 13.20 amps fed to

the NiCrome wire. This amount of damage is considered to be

negligible. Click on the photos of a larger photoA ounce of prevention is

worth 400 pounds of halon

-

- HOME

- US EPA, SNAP, ISO, ICAO, FAA US DOT, NFPA, SAE, FM, NIST, ATA, UL, SSL, AS/NZS, ODP , GWP , Pyrogen , PYROGEN , Airline Cargo conversions , Class A fire , Class B fire , Class C fire , EMAA, Encapsulated Micron Aerosol Agent, FAR 25. Aircraft Cargo Fires, Telecommunications fires , Transportation fires , Petrol chemical fires , Fire detection, Automobile Fire , Truck fires , Train fires , Building fires , Structural fires , petroleum fires , engine fires , marine fires , cargo fires , wood fires , Halon flooding , UL 1058, aircraft fire protection , aircraft crash , airline cargo fire , airline fire protection , FAA Technical center , Oil rig fires , gas rig fires , vehicle fires , electrical fire suppression , computer room fires , ship fires , machinery fires , merchant vessel fires , train fires , generator fires , battery fires , Wheel fires , brake fires , tire fires , car fires , home fires , Loss productivity , boeing fire test , 737 fire test , NRL , Naval Research Laboratory , Naval air systems command , NASC , NAVAIR , AS/NZS 4487:1997 , Joint strike fighter , JSF, HARC , NTSB , Transport canada , NIST , FAA Technical Center , Thermal Acoustic Insulation Blankets , IMO , International Maritime commission , USCG , United states coast guard , MCA , Pyrogen Ltd. Pyrogen Corp. Sdn. Bhd. , IAFC , IFPA ,